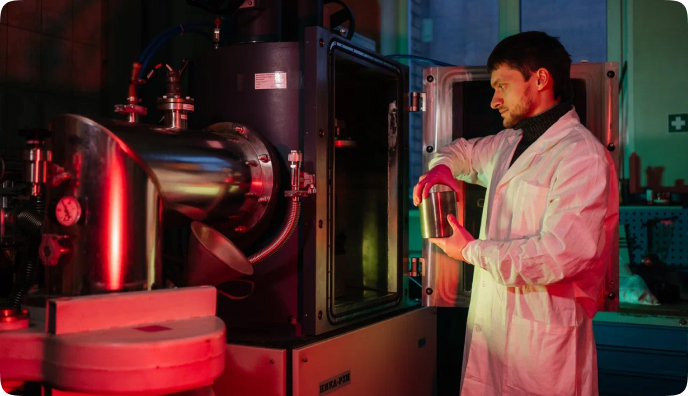

- Materials production and research

- Rare earth metals

The department's employees have accumulated unique experience in obtaining rare-earth metals. Over 20 mining and chemical-metallurgical enterprises have been built with their participation, and dozens of individual productions have been launched in non-ferrous metallurgy plants.

Currently, the main focus is on:

- Producing alloys, modifiers, and multi-component alloys;

- Manufacturing a new type of product for 3D technologies: spherical and polygonal powders of refractory metals (titanium, niobium, tantalum, molybdenum, tungsten, vanadium, rhenium), as well as powders with particle sizes ranging from 15 μm to 500 μm;

- Producing high-purity chlorides and fluorides of rare-earth metals;

- Recovering rare and rare-earth elements from oxides;.

- Producing powders with a purity of up to 5N in sealed glass ampoules, ranging from 1 gram to 100 grams

- Obtaining halides of rare-earth metals.

- Ability to produce a wide range of products

- Obtaining doped alloys with pre- determined properties

- Producing precision materials starting from 10 kg/year for each material

- Obtaining powder materials of refractory alloys for additive technologies and metallurgy

- Manufacturing custom- targeted chemical products according to customer's technical requirements